Co-Axial Wiring

We sell heavy duty co-axial wire that we get from Wilfried Schmidt in Germany. Schmidt uses it to connect their headlights to their dynamo hubs, as well as for taillight wiring that they make for us. But we also get this wire in big spools, and we can make up all sorts of wiring for different bikes. We can also sell you this co-axial wire in whatever length you need, up to 500 meters. By my calculations, that's long enough for one of those "bicycles built for 748." For bike shops we stock 5 meter, 10 meter and 100 meter spools. And of course we're happy to spend all day, every day, selling it for $1.00 per foot.

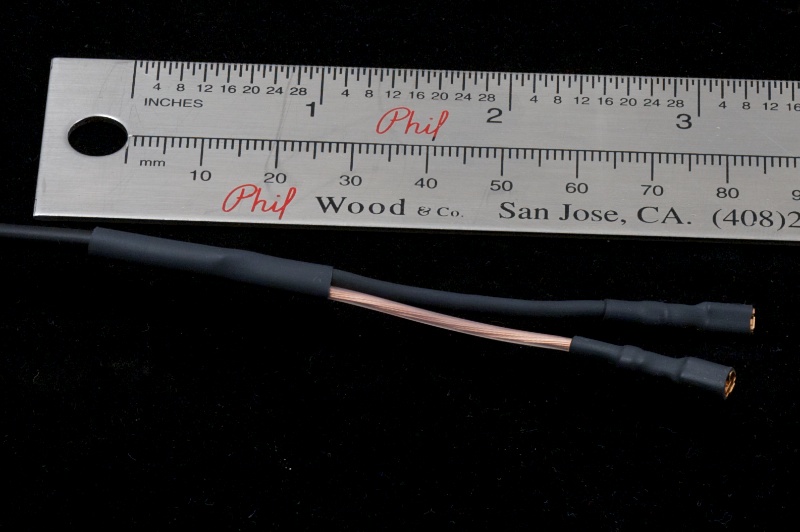

This wire is 3mm in diameter. There's a center core "power" covered by a clear insulator. Then the "ground" conductor wires are wrapped around that clear insulator and covered by a black outer insulator. The black outer insulator is .5mm thick.

The photos below show how to strip, crimp and insulate this wire with various connectors. The connectors shown are the 2.8mm connectors used by Busch & Müller for their headlight to taillight connections as well as their headlight to hub connections on certain headlights. The larger 4.8mm connectors used by Wilfried Schmidt for their hub connections attach in the same fashion. The only difference is that since the connectors are larger, you use a larger (1/4") shrink tubing to protect those 4.8mm connectors.

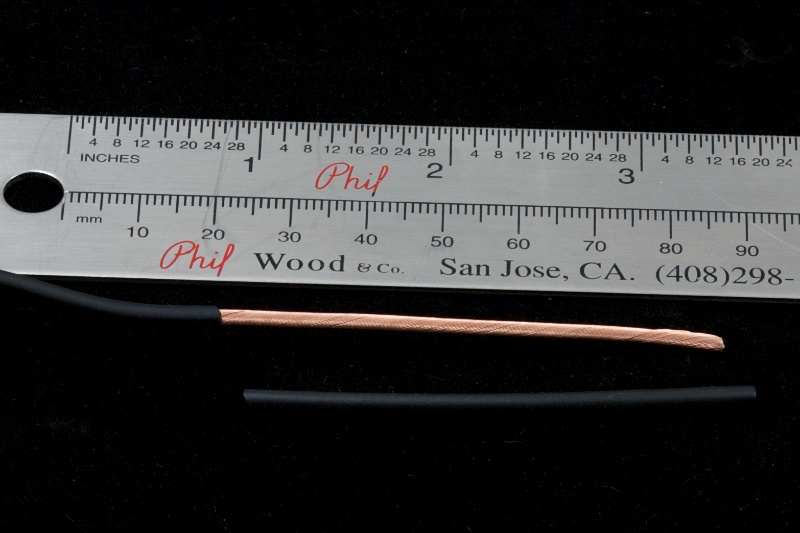

No, it's not an advertisement for Phil Wood. It's my spoke ruler shown here so you can easily see the scale. Here the outer insulator has been stripped off. You can see the "ground" wire strands wrapped around the inner core.

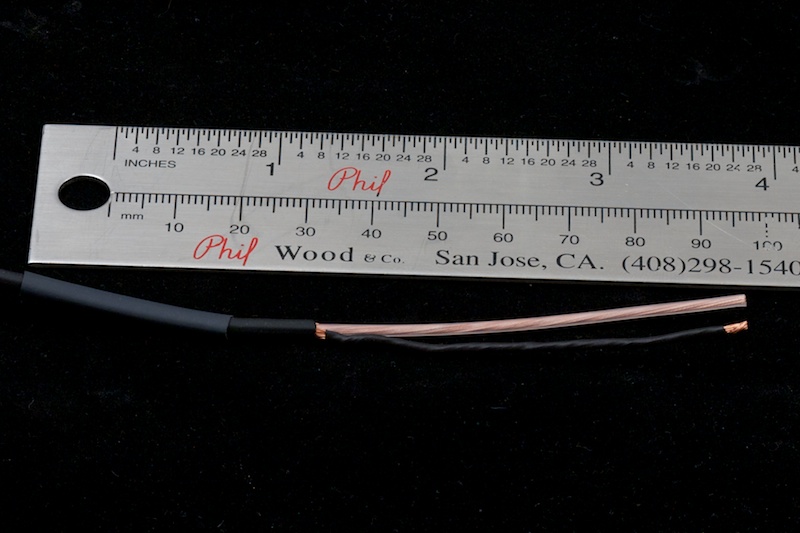

Here I've started to unwrap the "ground" wires. These are all very fine wires, and it's easy to leave a strand or two behind. If you do, you can end up with a short circuit. So be sure to capture them all.

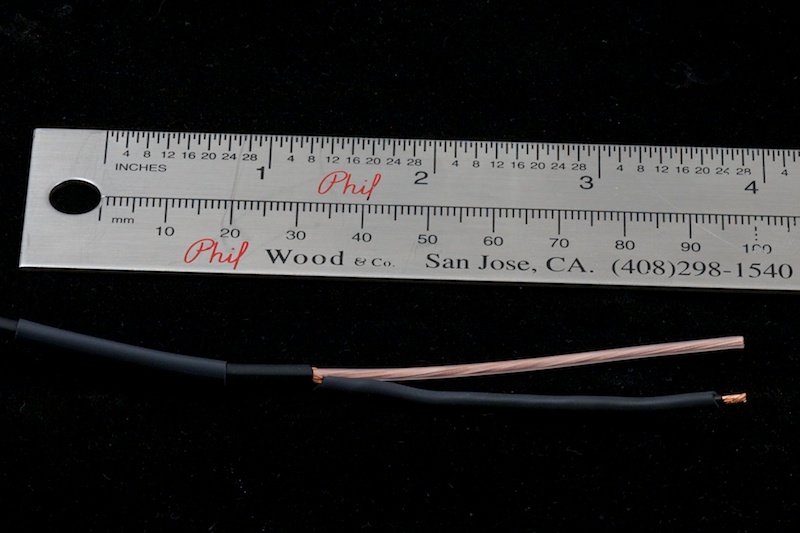

Here I've fully unwrapped the "ground" wire, slid on and heat shrunk a length of 1/16" heat shrink tubing. You can see the inner "power" wire inside the clear inner insulator. To the left you can see another piece of heat shrink tubing (1/8") that I've slid onto the wire to the left of the junction, but have not yet heated. That will cover up the junction once we're done.

And here I've taken another pieece of 1/8" shrink tubing and covered over the first smaller diameter piece. This large piece will add extra protection to the "ground" wire, and since it increases the overall diameter, it makes for a more secure "crimp" to the insulator. So, around the "ground" wire we have two pieces of shrink tubing. The first is 1/16" and the second is 1/8".

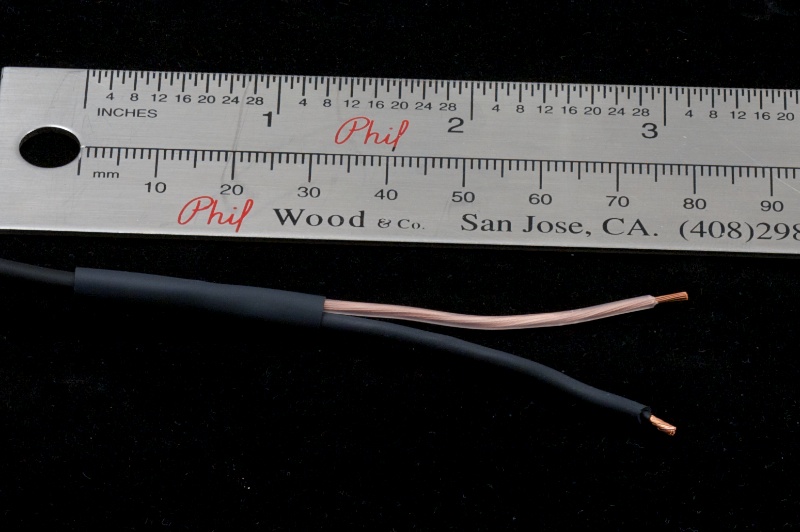

Here I've stripped the clear insulation from the end of the "power" or inner conductor, and I've slid the shrink tubing over onto the junction and heat shrunk it.

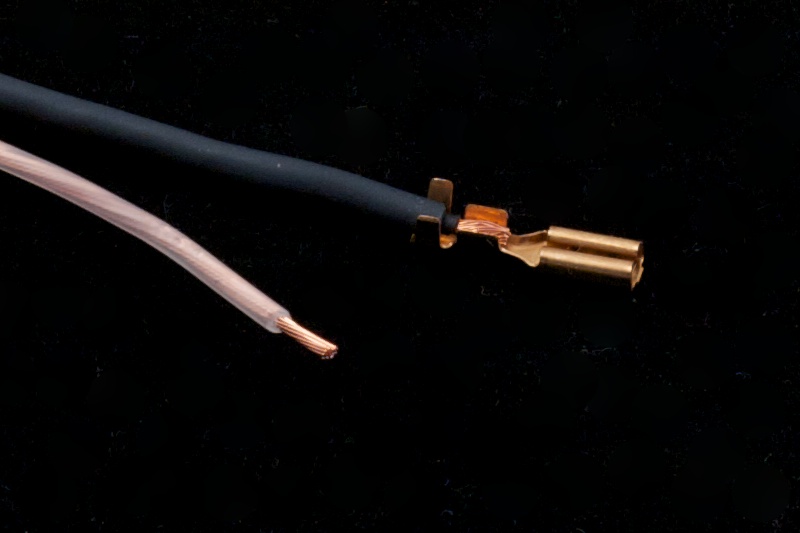

Here you see how the little crimps have two sets of ears. The set to the left is longer to wrap around the insulator. The set to the right are shorter; they only need to wrap around the conductor. And, this is important: Never solder these connectors. Only crimp them on, and always be sure you crimp to the insulator and to the conductor independantly. That way the insulator takes the stress while the conductor is left to do nothing but "conduct" electrons. All aboard!

And here you see the connector crimped onto the "ground" wire. I use a special crimping tool from Germany which does a great job. We sell two versions of these tools.

And here's the finished product, with both connectors crimped on and heat shrink tubing applied.

To see how to mount headlights and taillights, go to the mounting lights page.

Back to the Wiring Instructions page.

Back to Schmidt hub page

Back to Lighting Systems page

Back to: Peter White Cycles LLC home page

Penny is the Lord High Executioner of Email. So please send your email to Penny.

Mail to:

The email link above uses some fancy javascript voodoo to hide the actual address from spambots. Your browser needs to be set to run javascript in order for you to use any of the email links on my website. If you can't see the links, you can call us. You can also type the address into your email software. First, type the alias, "penny". Then type the "@" sign. It's above the number 2 on your keyboard. Then type the domain, "peterwhitecycles.com". Don't put in the quotes! That should do it.

You can also call us at 603 478 0900

It's best to call before 4PM Eastern time since after that we're either running around like headless chickens or at home ready to jump into the pot.

Please don't place an order without first reading this.

This page updated: Saturday, September 22, 2018

Peter White Cycles LLC

24 Hall Rd.

Hillsborough, NH 03244

USA

603 478 0900 Phone